Introduction

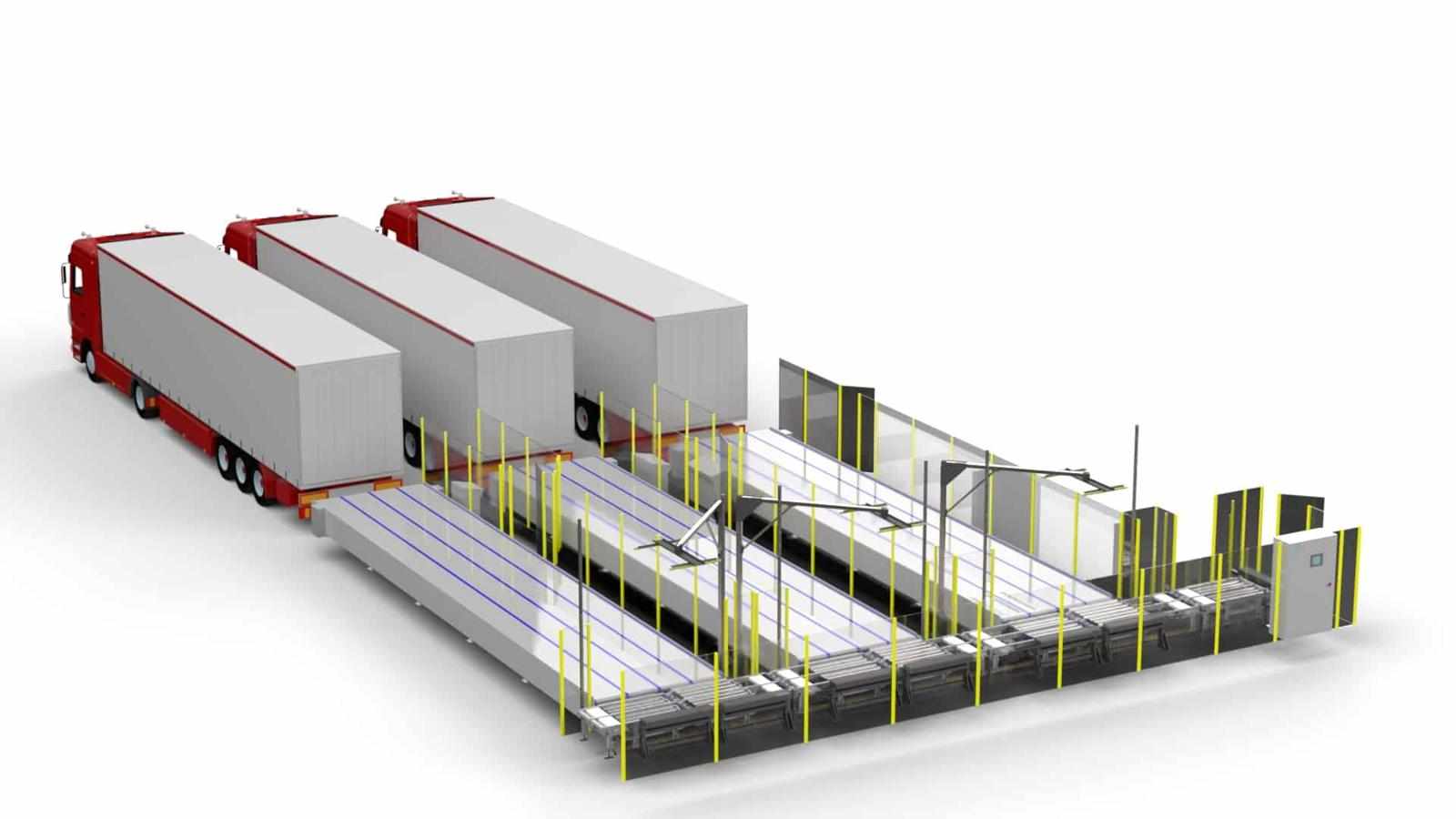

In the dynamic landscape of Finnish commerce, Small and Medium-Sized Enterprises (SMEs) form the backbone of the economy, driving innovation and contributing significantly to employment. However, these enterprises often face unique challenges in optimizing their logistics and supply chain operations, particularly when it comes to the time-consuming and labor-intensive process of loading and unloading goods. This is where the adoption of Automated Truck/Trailer Loading Systems (ATLS) presents a transformative opportunity. This comprehensive article delves into the burgeoning Finland ATLS Market specifically focusing on how affordable and scalable ATLS solutions can empower Finnish SMEs to overcome logistical hurdles, enhance efficiency, and achieve sustainable growth. We will explore the current market dynamics, the specific benefits ATLS offers to SMEs, the availability of scalable solutions, and the future outlook for this crucial technology in Finland.

Understanding the Finland ATLS Market: Growth Drivers and Key Players

The Finland ATLS market is currently experiencing a phase of significant growth, driven by several key factors:

Rising Labor Costs: As labor expenses continue to increase in Finland, SMEs are actively seeking cost-effective automation solutions to mitigate these rising operational costs.

Focus on Efficiency and Speed: In today's competitive environment, the ability to move goods quickly and efficiently is paramount. ATLS significantly reduces loading and unloading times, leading to faster turnaround times and improved overall efficiency.

Emphasis on Workplace Safety: Manual loading and unloading pose considerable risks of injury to personnel. ATLS solutions enhance workplace safety by minimizing human intervention in these hazardous tasks.

Increasing Adoption of Warehouse Automation: The broader trend of embracing automation within warehouses and logistics facilities across Finland is creating a favorable environment for the adoption of ATLS technologies as a crucial link in the automated supply chain.

Government Initiatives and Funding: Potential government initiatives and funding programs aimed at supporting SME digitalization and automation can further accelerate the adoption of ATLS in Finland.

While the market is still in its early stages of widespread adoption among SMEs, key global players in the automation and intralogistics sectors are actively exploring and catering to the Finnish market. Companies like KUKA AG and Jungheinrich AG, with their expertise in robotics, mobile automation, and integrated warehouse solutions, are positioned to offer relevant technologies for ATLS applications. Additionally, specialized ATLS manufacturers and integrators are emerging, providing tailored solutions for the specific needs of Finnish businesses.

The SME Advantage: Unlocking the Multifaceted Benefits of ATLS

For Finnish SMEs, the adoption of affordable and scalable ATLS solutions offers a multitude of compelling benefits that can significantly impact their bottom line and long-term sustainability:

Reduced Labor Costs: One of the most immediate and significant benefits is the reduction in the need for manual labor in loading and unloading operations. This translates directly into lower wage expenses and reduced reliance on temporary staff.

Increased Efficiency and Throughput: ATLS can dramatically accelerate the loading and unloading process compared to manual methods. This leads to faster turnaround times for vehicles, allowing for more deliveries or shipments within the same timeframe, ultimately increasing overall throughput.

Improved Workplace Safety: By automating the heavy lifting and repetitive tasks associated with loading and unloading, ATLS significantly reduces the risk of musculoskeletal injuries and other workplace accidents, creating a safer working environment 1 for employees.

Optimized Space Utilization: Faster loading and unloading can reduce congestion at loading docks and in warehouse areas, leading to better utilization of existing space.

Enhanced Accuracy and Reduced Damage: Automated systems are less prone to errors and mishandling of goods compared to manual processes, resulting in reduced product damage and fewer costly returns or replacements.

Scalability and Flexibility: Modern ATLS solutions are increasingly designed with scalability in mind. SMEs can often start with a basic level of automation and gradually expand their systems as their business grows and their needs evolve. Flexible designs can also accommodate different types of goods and loading/unloading scenarios.

Improved Supply Chain Visibility: Integration of ATLS with warehouse management systems (WMS) and other digital logistics tools can provide SMEs with better visibility into their supply chain, allowing for more informed decision-making and proactive problem-solving.

Enhanced Customer Satisfaction: Faster and more reliable delivery times, coupled with reduced product damage, contribute to improved customer satisfaction and stronger customer relationships.

Competitive Advantage: By embracing automation, SMEs can gain a competitive edge over businesses that rely on traditional, less efficient methods. This can be particularly crucial in attracting and retaining customers in both domestic and international markets.

Affordable and Scalable Solutions: Tailoring ATLS to SME Needs

A key concern for SMEs considering automation is often the initial investment cost and the perceived complexity of implementing such systems. However, the ATLS market is evolving to offer more affordable and scalable solutions specifically designed to meet the budgetary constraints and operational needs of smaller businesses:

Modular Design: Many ATLS solutions are now available in modular designs, allowing SMEs to invest in specific components that address their most pressing needs first and add further automation capabilities as their budget and requirements allow. For example, an SME might initially invest in an automated pallet conveyor system and later integrate it with robotic arms for more comprehensive automation.

Leasing and Financing Options: Recognizing the capital constraints of SMEs, many ATLS providers offer flexible leasing and financing options, making the technology more accessible without significant upfront investment.

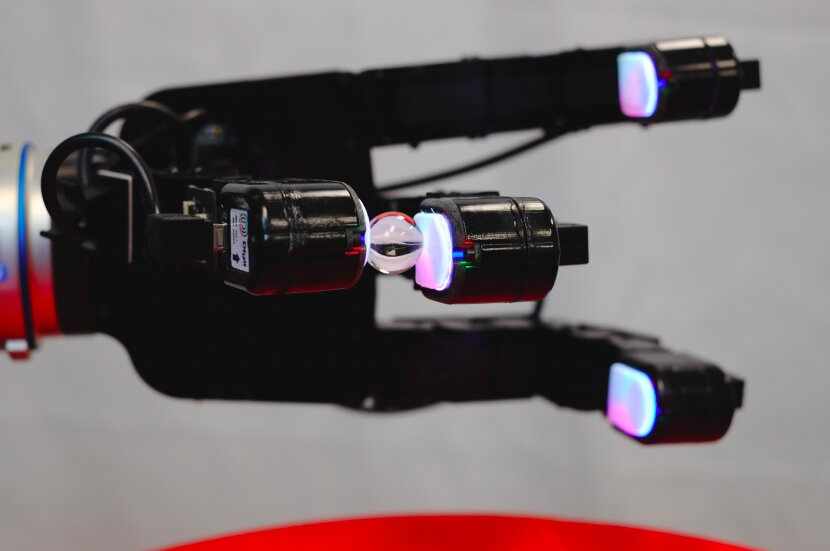

Collaborative Robots (Cobots): Cobots, designed to work safely alongside humans, can be integrated into ATLS applications for tasks like assisting with load securing or handling smaller items. Cobots often have a lower initial cost and require less complex integration compared to traditional industrial robots.

Standardized and Pre-Engineered Systems: The availability of standardized and pre-engineered ATLS modules can significantly reduce engineering costs and lead times, making automation more affordable for SMEs.

Software and Integration Solutions: User-friendly software interfaces and seamless integration with existing warehouse management systems are crucial for SMEs with limited IT resources. Providers are increasingly focusing on developing intuitive and easy-to-manage software solutions.

Focus on Specific Applications: Instead of investing in a fully automated system for all loading/unloading scenarios, SMEs can focus on automating specific bottleneck areas or repetitive tasks that offer the highest return on investment. For example, automating the unloading of frequently received goods.

Case Studies and Success Stories (Illustrative Examples)

While specific case studies of ATLS adoption by Finnish SMEs might still be emerging, we can draw parallels from SMEs in other European countries that have successfully implemented such solutions. For instance:

A small Finnish woodworking company could invest in an automated system to load and unload timber onto trucks, reducing the physical strain on their workers and speeding up delivery times to construction sites.

A medium-sized food processing SME could utilize an ATLS to efficiently load pallets of finished goods onto refrigerated trucks for distribution to supermarkets, ensuring timely delivery and minimizing potential spoilage.

An e-commerce fulfillment center in Finland could implement a scalable ATLS solution to handle the increasing volume of outgoing parcels, improving dispatch efficiency and reducing the risk of shipping errors.

These illustrative examples highlight the diverse applications and potential benefits of ATLS across various SME sectors in Finland.

Overcoming Implementation Challenges for Finnish SMEs

While the benefits of ATLS are clear, SMEs in Finland might face certain challenges during the implementation process:

Initial Investment Cost: Even with more affordable options, the initial investment can still be a barrier for some SMEs. Thorough ROI analysis and exploring financing options are crucial.

Integration with Existing Systems: Ensuring seamless integration of the ATLS with existing warehouse management systems, enterprise resource planning (ERP) software, and other logistics tools is essential for maximizing efficiency.

Technical Expertise and Training: SMEs may lack the in-house technical expertise to install, operate, and maintain sophisticated ATLS systems. Choosing providers that offer comprehensive training and ongoing support is vital.

Space Constraints: Some SMEs, particularly those operating in older facilities, might have limited space available for implementing large-scale automation. Compact and flexible ATLS designs are essential in such cases.

Change Management: Introducing automation can require significant changes in workflows and employee roles. Effective communication and change management strategies are crucial for successful adoption.

The Future of ATLS for Finnish SMEs: Trends and Opportunities

The future of the Finland ATLS market for SMEs looks promising, with several key trends and opportunities on the horizon:

Increasing Affordability: As the technology matures and competition increases, ATLS solutions are expected to become even more affordable and accessible to SMEs.

Greater Scalability and Flexibility: Future ATLS designs will likely offer even greater scalability and flexibility, allowing SMEs to adapt their systems to changing business needs and handle a wider range of goods.

Integration with AI and Robotics: The integration of artificial intelligence (AI) for optimizing loading patterns and robotic arms for more complex handling tasks will further enhance the efficiency and versatility of ATLS.

Cloud-Based Monitoring and Management: Cloud-based platforms will enable SMEs to remotely monitor and manage their ATLS operations, facilitating proactive maintenance and data-driven decision-making.

Focus on Sustainability: Future ATLS solutions will likely incorporate more energy-efficient components and contribute to the overall sustainability goals of Finnish SMEs.

Government Support and Incentives: Increased government support and financial incentives for SMEs investing in automation technologies could significantly accelerate the adoption of ATLS in Finland.

Conclusion

The Finland ATLS market presents a significant opportunity for Small and Medium-Sized Enterprises to overcome their logistical challenges, enhance efficiency, improve safety, and achieve sustainable growth. By embracing affordable and scalable ATLS solutions, Finnish SMEs can unlock a range of benefits, from reduced labor costs and increased throughput to improved customer satisfaction and a stronger competitive edge.

While implementation challenges exist, the evolving landscape of ATLS technology, with its focus on modularity, affordability, and ease of integration, is making automation increasingly accessible to SMEs. As the Finland ATLS market continues to mature and innovative solutions become more readily available, the adoption of these technologies will play a crucial role in empowering Finnish SMEs to thrive in the increasingly competitive global marketplace. By carefully evaluating their needs, exploring available options, and partnering with experienced providers, Finnish SMEs can strategically leverage the power of ATLS to build more efficient, resilient, and future-proof logistics operations.

Write a comment ...