Introduction

India's ambitious goals for renewable energy expansion are creating unprecedented opportunities across various manufacturing sectors. From the towering structures of wind turbines to the vast arrays of solar panels, the need for precise and efficient manufacturing processes is paramount. Within this dynamic landscape, CNC deep hole drilling emerges as a critical, yet often overlooked, technology with immense potential to unlock greater efficiency, quality, and innovation within India's renewable energy sector.

The India CNC Drilling Machine Market is already experiencing robust growth, driven by the increasing demand for automation and precision across industries. As the renewable energy sector scales up, the demand for specialized drilling capabilities, particularly deep hole drilling, will only intensify. This article delves into the untapped potential of CNC deep hole drilling within India's renewable energy manufacturing ecosystem, exploring its applications, benefits, and the strategic implications for the burgeoning market.

Understanding CNC Deep Hole Drilling: Precision at Depth

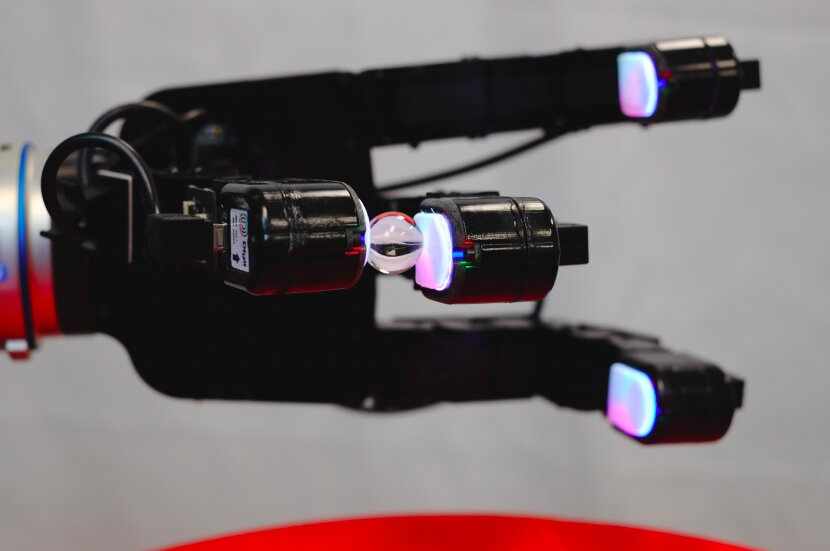

Traditional drilling methods often struggle with creating accurate and consistent holes with high depth-to-diameter ratios. This is where CNC deep hole drilling excels. Utilizing specialized tools, advanced machine designs, and precise computer numerical control, this technology enables the creation of deep, straight, and smooth holes with exceptional accuracy and surface finish.

Key techniques within CNC deep hole drilling include:

Gundrilling: A single-flute drill with internal coolant supply, ideal for creating precise, deep holes in a single pass.

BTA (Boring and Trepanning Association) Drilling: Employing a drill head with multiple cutting inserts and external/internal chip evacuation, suitable for larger diameter deep holes.

Ejector Drilling: A variation of BTA drilling that uses a double tube system for efficient chip removal.

The integration of CNC technology ensures repeatability, accuracy, and the ability to handle complex drilling operations required for various renewable energy components.

The Untapped Potential: Applications in India's Renewable Energy Sector

The applications of CNC deep hole drilling within India's renewable energy sector are diverse and hold significant potential for enhancing manufacturing processes:

1. Wind Energy:

Gearbox Components: Deep hole drilling is crucial for creating precise oil passages within wind turbine gearboxes. These passages ensure proper lubrication and cooling, critical for the longevity and efficiency of these high-torque systems. The accuracy achieved with CNC deep hole drilling minimizes the risk of leaks and ensures optimal performance.

Main Shafts and Rotor Hubs: Long and precise holes are required for bolting and hydraulic systems within the main shafts and rotor hubs of wind turbines. CNC deep hole drilling guarantees the structural integrity and precise alignment necessary for safe and efficient operation.

Blade Manufacturing: While not direct drilling in the conventional sense, the principles of precision and controlled material removal inherent in CNC deep hole drilling can inspire innovative techniques in creating complex internal structures within wind turbine blades, potentially enhancing their strength and reducing weight.

2. Solar Energy:

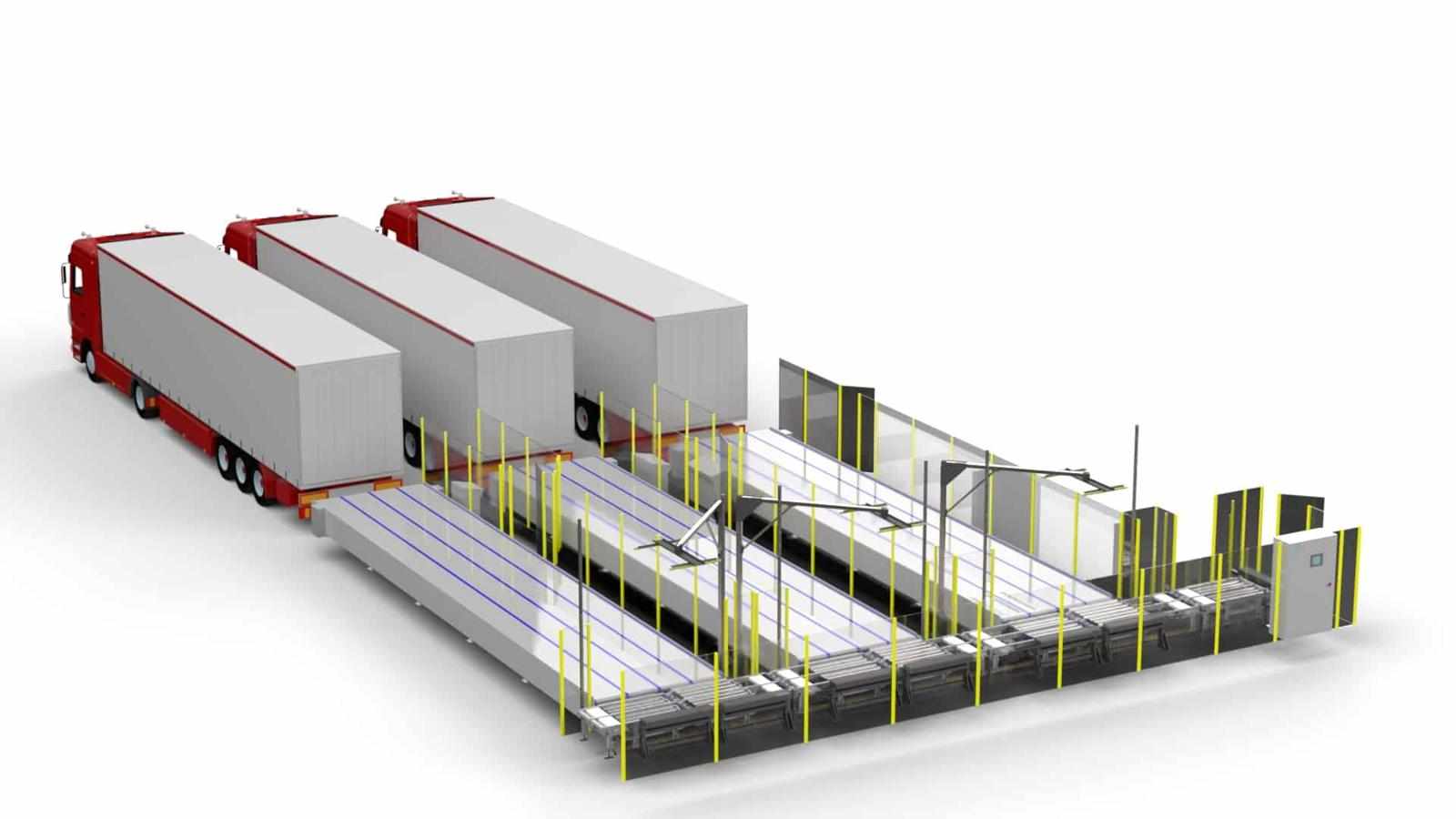

Solar Panel Mounting Structures: Deep and accurate holes are required for the secure bolting and anchoring of solar panel mounting structures, especially in large-scale solar farms. CNC deep hole drilling ensures the stability and durability of these installations, crucial for withstanding environmental stresses.

Heat Exchangers in Concentrated Solar Power (CSP): CSP plants utilize complex heat exchangers. CNC deep hole drilling can be employed to create intricate internal channels for efficient heat transfer fluids, maximizing energy capture and conversion.

Manufacturing of Polysilicon Production Equipment: The production of high-purity polysilicon, a key component in solar cells, requires specialized equipment with precisely drilled components for fluid and gas transfer. CNC deep hole drilling can contribute to the efficiency and reliability of this manufacturing process.

3. Hydropower:

Turbine Shafts and Components: Similar to wind turbines, hydropower systems rely on large shafts and complex components requiring precise deep hole drilling for lubrication, cooling, and structural integrity.

Valve Bodies and Actuators: Accurate deep holes are essential for the hydraulic systems that control water flow in hydropower plants, ensuring efficient and reliable operation.

4. Other Renewable Energy Sources:

Geothermal Energy Systems: Drilling deep and accurate holes is fundamental to geothermal energy extraction. While not directly the same as component manufacturing, the expertise in deep drilling technology can be valuable for companies involved in this sector.

Bioenergy Processing Equipment: Certain components in bioenergy processing plants may require precise drilling for fluid transfer and mechanical linkages.

Benefits of CNC Deep Hole Drilling for India's Renewable Energy Manufacturing:

Adopting CNC deep hole drilling in India's renewable energy sector offers numerous advantages:

Enhanced Precision and Accuracy: Achieving tight tolerances and precise hole dimensions is critical for the performance and longevity of renewable energy components. CNC deep hole drilling guarantees this level of accuracy, leading to improved efficiency and reduced material waste.

Improved Surface Finish: The smooth surface finish achieved with deep hole drilling techniques minimizes friction and wear in moving parts, such as gearbox components, extending their lifespan and reducing maintenance requirements.

Increased Efficiency and Productivity: CNC automation allows for faster cycle times and consistent results, leading to higher production volumes and reduced manufacturing costs.

Complex Geometries and Deep Ratios: CNC deep hole drilling can handle challenging drilling tasks with high depth-to-diameter ratios and complex angles, enabling the manufacturing of advanced component designs.

Reduced Tool Wear: Advanced cooling systems integrated into deep hole drilling machines effectively remove heat and chips, extending tool life and improving machining accuracy.

Integration with Industry 4.0: Modern CNC deep hole drilling machines can be integrated with sensors and data acquisition systems, enabling real-time monitoring, predictive maintenance, and optimized production processes in line with Industry 4.0 principles.

Material Versatility: CNC deep hole drilling can be applied to a wide range of materials used in renewable energy components, including steel, aluminum alloys, and specialized composites.

Strategic Implications for the India CNC Drilling Machine Market:

The growing demand from the renewable energy sector presents significant opportunities for the India CNC Drilling Machine Market. To capitalize on this potential, several strategic considerations are crucial:

Skill Development and Training: As the adoption of CNC deep hole drilling increases, there will be a growing need for skilled operators and maintenance personnel. Investing in training programs and educational initiatives will be essential to build a competent workforce.

Technology Transfer and Localization: Encouraging technology transfer and the localization of CNC deep hole drilling machine manufacturing in India can reduce costs and lead times for domestic renewable energy manufacturers.

Focus on Application-Specific Solutions: CNC machine manufacturers should focus on developing and offering deep hole drilling solutions tailored to the specific requirements of the wind, solar, and other renewable energy sub-sectors.

Integration of Automation and Digitalization: Incorporating automation and Industry 4.0 capabilities into CNC deep hole drilling machines will be crucial to meet the demands for efficiency and data-driven manufacturing in the renewable energy sector.

Collaboration and Partnerships: Fostering collaboration between CNC machine manufacturers, tooling providers, and renewable energy component manufacturers can drive innovation and the development of optimized drilling solutions.

Government Support and Incentives: Government policies that encourage the adoption of advanced manufacturing technologies, including CNC deep hole drilling, will play a vital role in accelerating growth within the renewable energy sector.

Overcoming Challenges and Realizing the Potential:

While the potential is significant, there are challenges to address:

Initial Investment Costs: CNC deep hole drilling machines can have a higher initial cost compared to conventional drilling equipment. However, the long-term benefits of increased efficiency, accuracy, and reduced waste can offset this investment.

Technical Expertise: Operating and maintaining sophisticated CNC deep hole drilling equipment requires specialized knowledge and skills. Investing in training and development is crucial.

Awareness and Adoption: Raising awareness about the benefits and applications of CNC deep hole drilling within the renewable energy sector is essential to drive adoption.

Conclusion

The India CNC Drilling Machine Market stands at the cusp of a significant opportunity driven by the nation's ambitious renewable energy goals. CNC deep hole drilling, with its inherent precision, efficiency, and ability to handle complex tasks, holds immense untapped potential to revolutionize the manufacturing of critical components for wind turbines, solar panels, and other renewable energy systems.

By strategically focusing on skill development, technology transfer, application-specific solutions, and embracing Industry 4.0 principles, India can unlock the full potential of CNC deep hole drilling. This will not only enhance the competitiveness and quality of India's renewable energy manufacturing sector but also contribute significantly to the nation's journey towards a sustainable and green future. The time is ripe for Indian manufacturers to explore and adopt this advanced technology, drilling down to a future powered by precision and sustainability.

Write a comment ...